Non Linear FEA, Metals and Metal Forming

Utilizing Simufact metal simulation software, Innova has strong capabilities in both bulk forming (hot forging) and cold forming simulation of metals. Virtually every type of metal forming application can be simulated- accurately and quickly. Our metals database includes full TTT curves, grain size predication, and micro structure data.

A quick list of metal forming simulation capabilities:

Hot Forging

- Bulk Forming

- Upsetting

- Cogging

- Forward extrusions

- Backward extrusion

- Gear forming

- Open die

Cold forming

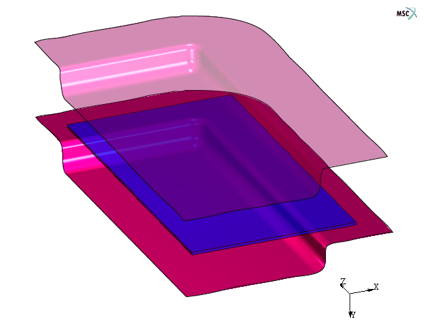

- Deep drawing

- Stretch forming

- Stamping/blanking

- Multi-stage forming

- Metal spinning

- Cold heading

- Bending

- Rolling

- Transverse rolling

- Ring rolling

Welding/ Mechanical Joining

- Spot welding

- Arc welding

- Line welding

- Rivets

- Bolts

- Clinching

- Machining simulation

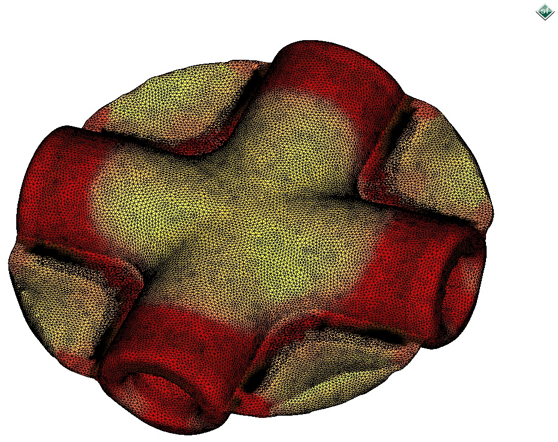

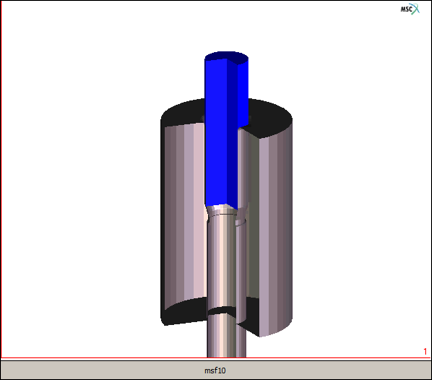

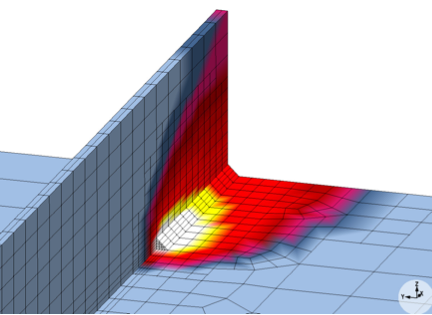

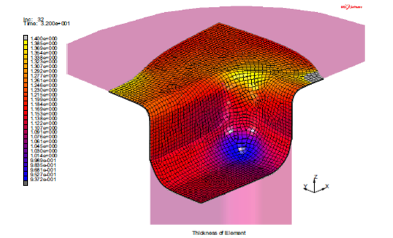

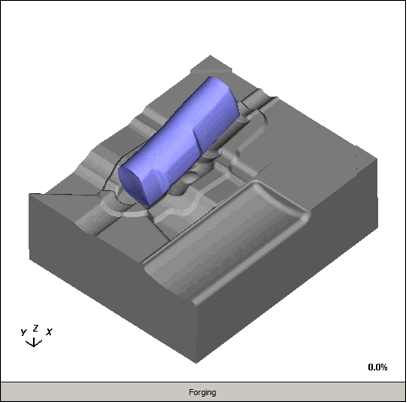

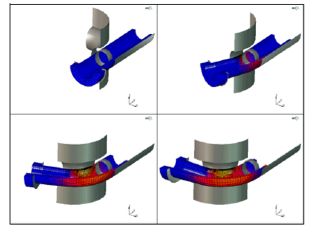

Figure 1.) Multi-axis forging

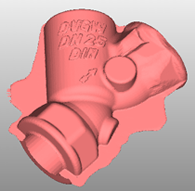

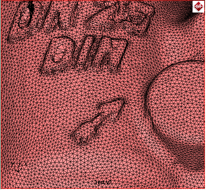

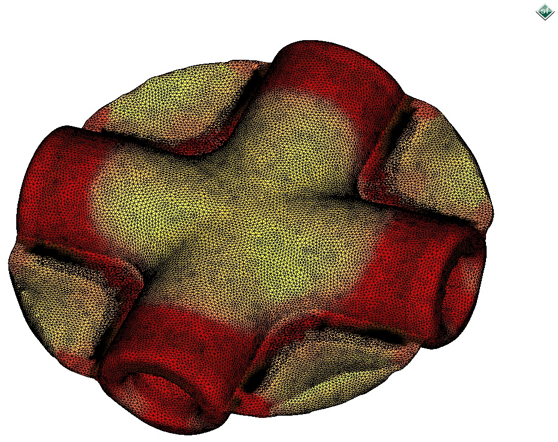

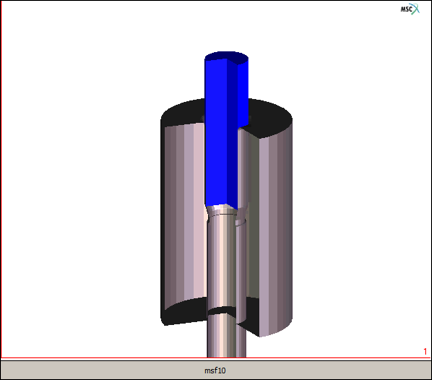

Figure 2.) Hot forging

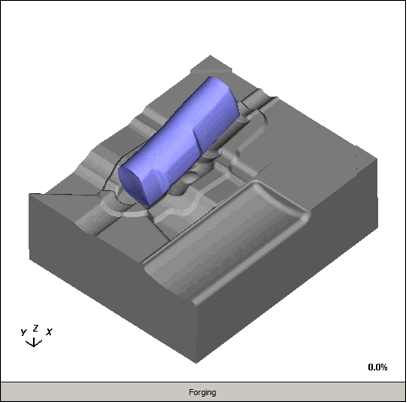

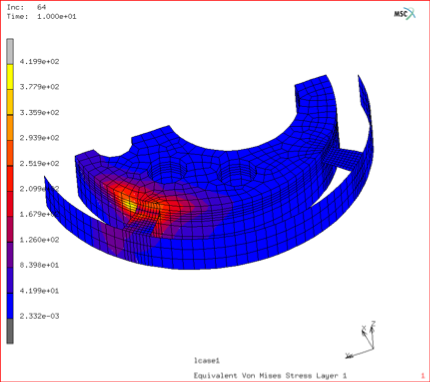

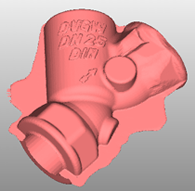

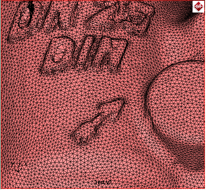

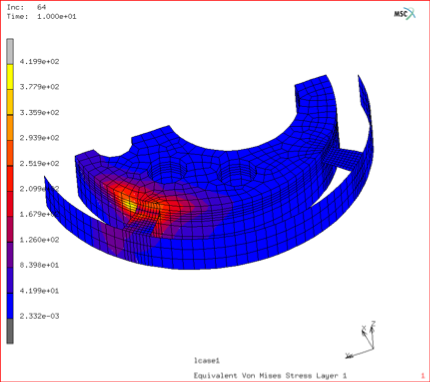

Figure 10.) Cold heading

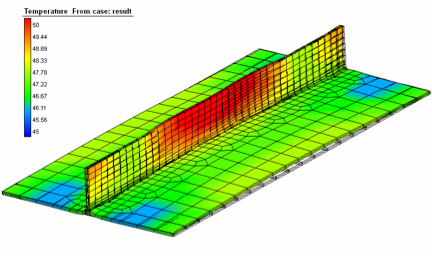

Figure 11.) Path welding

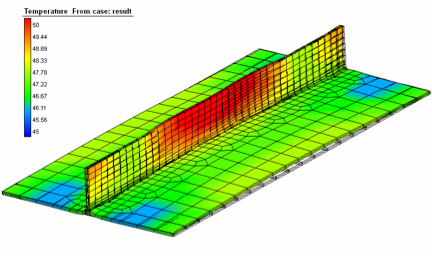

Figure 12.) Distortions after welding

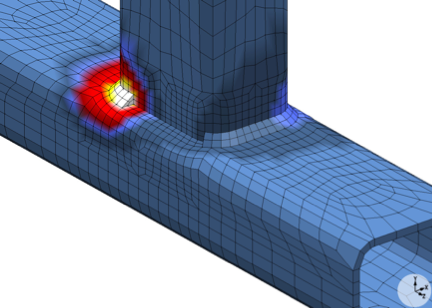

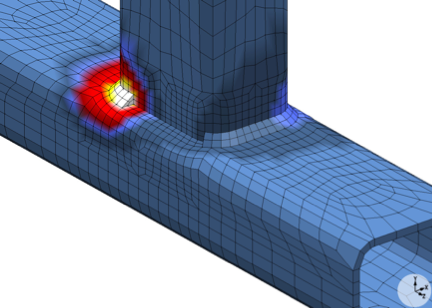

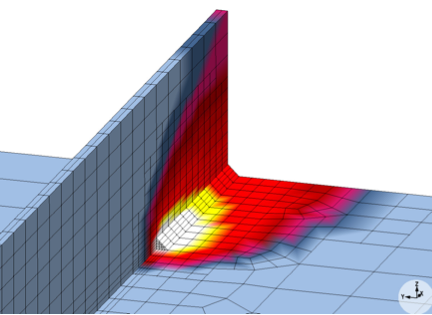

Figure 13.) Aluminum T joint Simulation

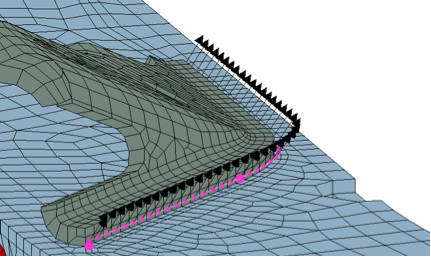

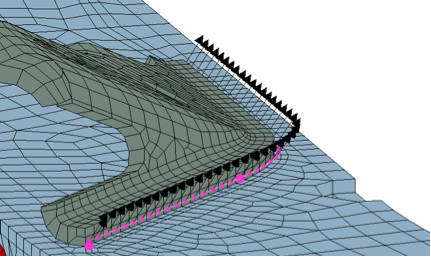

Figure 14.) Adaptive mesh refinement

Figure 15.) Arc welding simulation

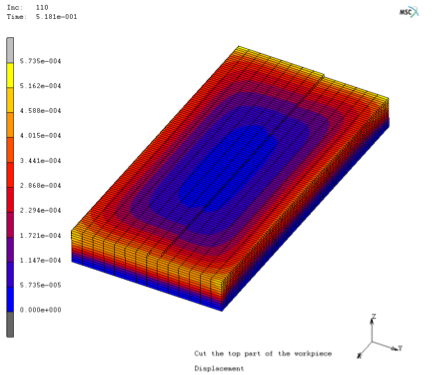

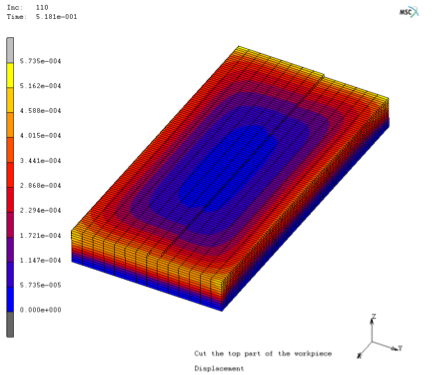

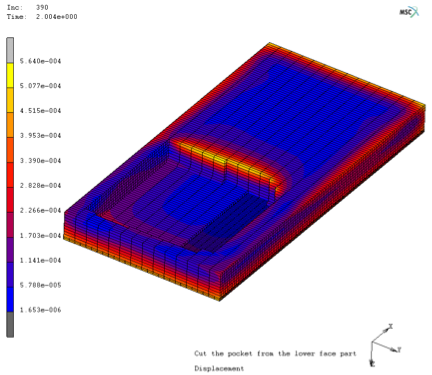

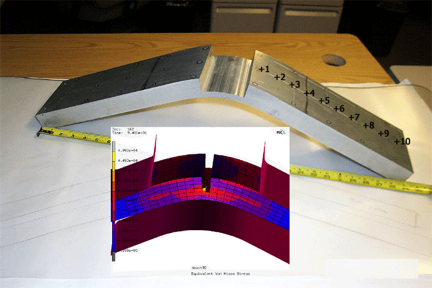

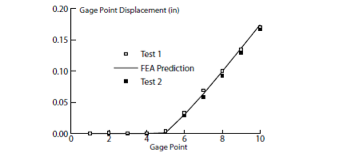

Figure 16.) Machining- material removal simulation

Figure 17.) Machining- material removal simulation

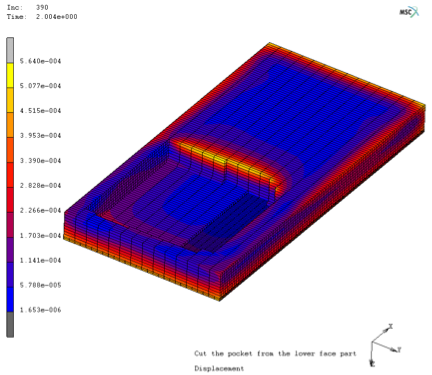

Figure 18.) Machining- material removal simulation, residual stresses

Figure 19.) Machining- material removal simulation, residual stresses

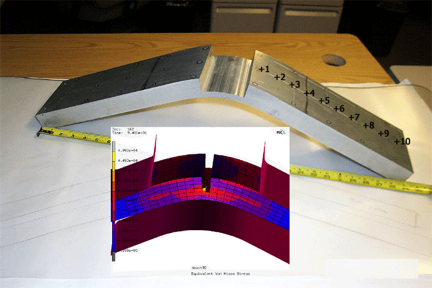

Figure 20.) Roll bending

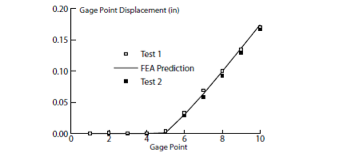

Figure 21.) Drawing

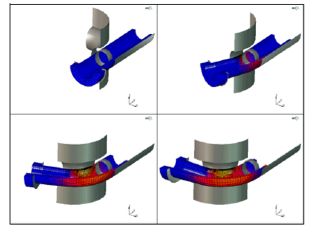

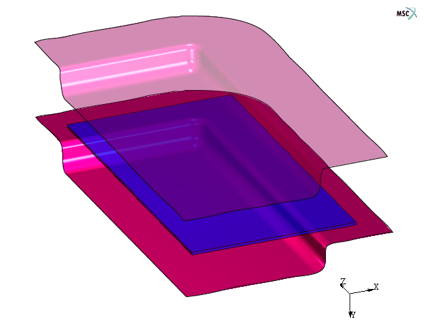

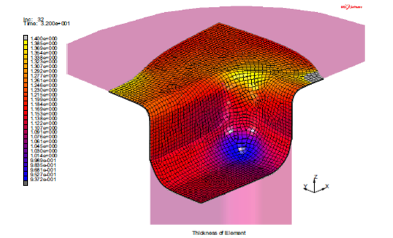

Figure 22.) Deep Drawing